Following on the footsteps of Mazda’s technological leap in controlling the combustion process – enabling both spark (typical gas engine power) and compression ignition (typical diesel efficiency) – Nissan is now showing off its production ready game changer of an engine. Instead of varying the ignition method, it utilizes a variable compression ratio to achieve a similar end game.

Demonstrating a revolutionary advance in the design of the traditional gasoline engine construction, Nissan’s variable compression (CR) technology will debut with the new 2019 Infiniti QX50 (Nissan owns Infinity).

This VC-Turbo engine, a 2.0-liter four-cylinder turbo, provides the power expected of a modern 2.0-liter turbo four while also delivering the efficiency of a modern diesel just without its costly emission gear. Basically, we can have our cake and Nissan says we can eat it too.

Today’s generation of engines can feature many methods to vary the inputs and precisely control each combustion process, enabling more power, cleaner emissions, and increased fuel economy.

Camshafts

The timing of the controlled explosion, the duration that intake and exhaust valves remain open, and even how far they extend to the chamber were all once static compromises but now live commonly in the variable world.

Fuel Injection

The location of where the fuel is added is also variable as automakers fit two fuel injectors per cylinder – one inside (direct injection) and one outside (port injection) of the cylinder – to gain benefits that each uniquely provides.

Cylinders

Active cylinder management allows engines to essentially turn off a certain number of cylinders and only reconnect the valves and turn on the fuel and spark when the additional power is requested.

Forced induction

Advances in combustion monitoring controls have also enabled reliable turbocharging and supercharging systems which can be widely tuned for driveability and performance. However, this forced induction pushes the current limits of controls that are based on a static CR.

…and the once static CR

Despite these numerous variable inputs to the combustion process, the compression ratio has remained a significant static compromise. Defined as the ratio between the maximum chamber volume (piston is at the bottom of the stroke) and the minimum volume (piston is at the top of the stroke), a high CR is more efficient as the same potential energy is translated into more piston motion. However, in today’s world where big power gains are possible from forced induction, a lower compression ratio is necessary to prevent an uncontrolled explosion from pre-detonation.

Thus there are two opposing directions between power and efficiency that guide the static CR compromise. But the customer wants improvements in power and efficiency!

Over the years, automakers have explored different methods to enable a variable CR but none have been reached the mass-production stage for one reason or another, until now.

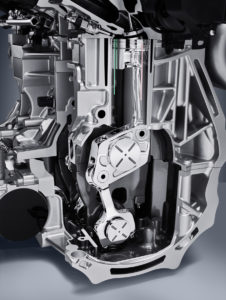

Although Nissan’s system is very technical and precise, the overall concept it rather simple – an attribute common with great engineering designs. It starts with the piston’s connecting rod that is now fixed to the end of a lever instead of the crankshaft. The middle of the lever attaches to the crankshaft and the opposite end is attached to another connecting rod which, in turn, is connected to the control shaft (Nissan’s terminology). The control shaft lies at the bottom of the engine and features an eccentric shape so when it is rotated by a specially developed gear motor, the angle of the secondary connecting rod is changed relative to the crankshaft and thus driving the change in the lever’s angle. This new angle, changes the overall height to which the top of the piston travels and therefore is able to vary the CR depending on how much power is necessary.

Other advantages

Besides a wide ranging CR (8:1-14:1), there are other numerous advantages of the design. Because the lever now translates the linear motion of the piston to the rotational motion of the crankshaft, the crankshaft is able to be offset to align with the centerline of the piston, thereby allowing for a nearly vertical power (expansion) stroke.

And because the piston is no longer expanding at an angle, unwanted vibrations are reduced so much so that Nissan has been able to do away with the traditionally required counterbalance shafts. Despite the added motor, rods, and shaft, the engine will fit in a space similar to a conventional four-cylinder engine while still managing a 55 lbs weight reduction compared the V6 that it replaces. Although peak power is stated at 268 hp and 288 ft*lb, these values are only a snapshot of the true power benefits this engine is capable of delivering.

Not to be left aside, the previously mentioned modern features and controls are also present; certainly helping contribute to a 27% fuel efficiency improvement (from the V6) and wide powerband.

Despite the attention surrounding the advancement of electrified power units (which is exciting in its own right!), the combustion engine will remain as a key component to meeting customer expectations and emissions regulations well into the later half of this century. This design breakthrough will, in no doubt, elevate the expectations of what is possible with spark ignition engines. For that, it deserves at least a few headlines.

Wow. That video is pretty impressive. The second you think there isn’t much else to improve on with an internal combustion engine, some one proves you wrong 🙂